LCI Furnaces

LCI Furnaces

LCI Furnaces

INDUSTRIAL FURNACE DIVISION

INDUSTRIAL FURNACE DIVISION

INDUSTRIAL FURNACE DIVISION

Thin Film Applications

Thin films are primarily found in photovoltaic systems, commercial construction materials, electronic semiconductor devices, optical coatings and art ceramic and dichroic glass applications. Coatings applied in layers as thick as 10 micrometers to less than a nanometer often benefit from infrared firing.

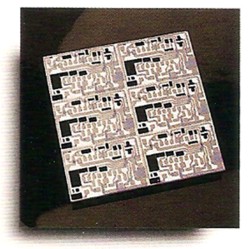

hin film to various media in many different applications. sed in the production of electronic devices, thick film technology uses conductive, resistive and insulating pastes or inks (Noble metal, ceramic or glass ink) screen printed in patterns which are ultimately fused at high temperatures. After screen-printing and curing of the paste, thick film circuits typically require a firing stage at a high temperature (500-1000°C) to fix the layers permanently on the substrate.

The substrates are fired by passing the substrates on a continuous belt through a multi-zone furnace. In this furnace the parts are exposed to a number of phases including organic burnout, softening/melt, resistive compound formation, solidification, and finally annealing. Because of their ability to introduce high temperature quickly and precisely control temperatures in subsequent phases, infrared furnaces are used successfully in production environments for this purpose. Since substrates are able to absorb energy very rapidly from infrared sources, using an IR furnace can result in fire rates 3 to 4 times faster than conventional convection furnaces.

Infrared Furnaces and Thin Film Processing

Continuous belt infrared firing of thin film materials can ofter improve on batch furnace output by a factor of 3-10 times. The short warmup time saves time. A high degree of consistency can be achived since prodution unit travels through the same environment. Each subsequent unit receives the same heat energy as the last. Compare this to a conventional batch furnace which may exhibit temperature stratification various positions in the kiln. The physical structure of thick film materials is developed very quickly, and the overall time/temparature product is relatively small.

Figure 1: Firing of thin film coating on optical lens

Because of the very rapid internal accumulation of temperature during the volatile burnout stage, due to high ambient atmosphere temperature (850-950°C) and the peneterating power of high intensity short wave radiation, the organic volatiles within the inks essentially sublime completely from the structure without eruption. Structure depths up to 300 microns thickness are possible without the unacceptable diffusions and migrations of materials encountered in conventional processing.

Thick Film Profiling in an IR Furnace

For most thick film processes in these infrared furnaces, the rate of temperature rise in the product can be made quite fast, the volatilization and sublimation of organic binders being completed long before polymerization of fusion temperatures are attained. To achieve this result, the first zone is driven as hard as practical to maintain the highest intensity short wave radiation (near infrared), reaching process temperature at the beginning of subsequent holding zone(s). The holding zones are set to produce process fusion or polymerization temperatures in the product. Dwell time in these zones should be just sufficient to drive the pyrolysis or polymerization to completion. By limiting the time at temperature in this manner, unacceeptable migrations or diffusions can be avoided.

Testing has shown that substrate cracking is somewhat, if not entirely, dependent on cooling rates. The cooling system should be adjusted to provide cooling rates consistent with high yield and throughput without promoting cracking.

Controlled Atmosphere

Critical to the process, the atmosphere must be controlled with clean dry process gas to prevent contamination of the paste. For most processes (except copper paste) the clean dry air (CDA) is supplied an effective and economical process gas. The preferred method of introduction of process gas in an IR furnace is through the furnace walls with gas supplied in the first zone at twice the rate as in subsequent zones. Process gas and volatiles are drawn toward the entrance of the furnace and out a venturi assist exhaust stack.