LCI Furnaces

LCI Furnaces

LCI Furnaces

INDUSTRIAL FURNACE DIVISION

INDUSTRIAL FURNACE DIVISION

INDUSTRIAL FURNACE DIVISION

Overview

The ProControl furnace control system uses an industrial programmable logic controller (PLC) with an ethernet connected furnace computer (OIT). The furnace computer is used to communicate with the PLC via ProControl software in a Windows(tm) operating system.

The ProControl OIT interface offers many features, including multilayer password protection, the ability to store and rapidly change recipes, view current and past operating behavior and activity & error logging.

Furnaces with a ProControl OIT system use a control console like the onei illustrated in Figure 1 to start the furnace and engage the contol system. As you can see from the screen shots below, the software is intuitive and easy to use for Operators, yet offers the Process Engineer sophisticated features for PID control and analysis.

(Click on any of the screen shots below to view larger versions.)

OIT Operator Interface Control Console

The operating parameters and control of all integrated furnace systems is via an furnace conputer or Operator Interface Terminal (OIT) that enables the Process Engineer to set and view furnace process operating parameters. The Process Engineer can store the process parameters in recipes. The recipes can then be loaded into the furnace program by the furnace Operator.

Figure 2. Furnace Operator Interface Terminal (OIT)

ProControl Splash and Security screens

When started, the OIT automatically loads the ProControl software. After the Splash screen disappears, the Operator can login on the Security screen. The Security screen allow Engineer level to add, delete and modify users, user levels and passwords.

Figure 3. Splash and Security screens

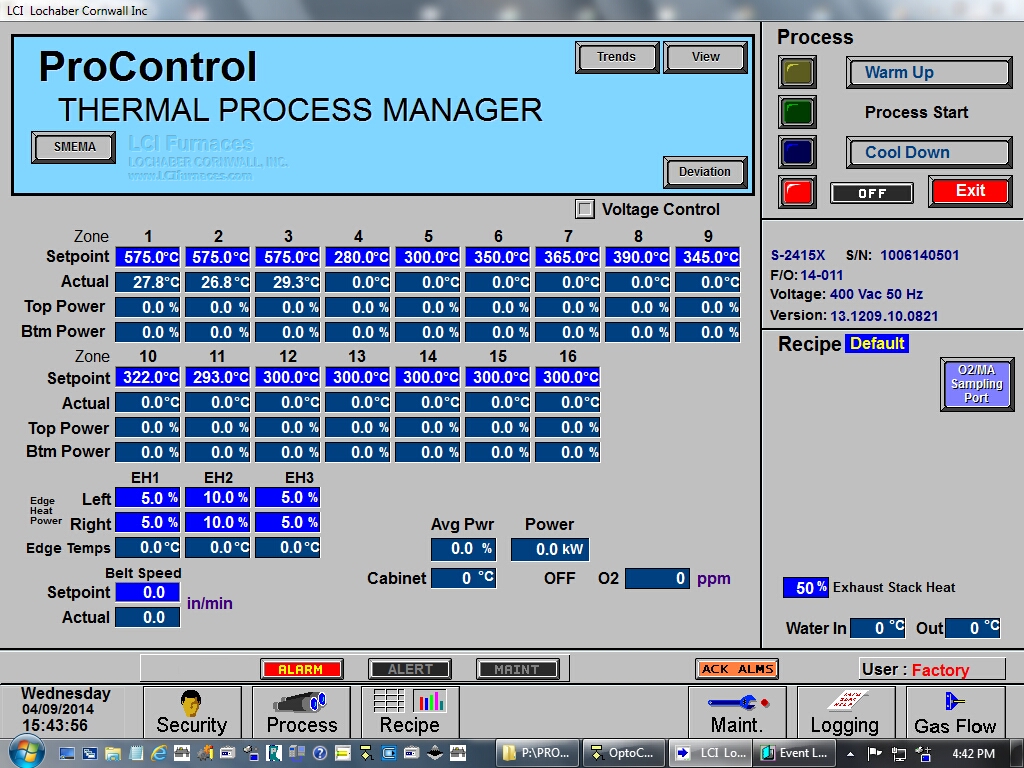

The Process screen

Most of furnace operating parameters and data can be viewed from the Process screen in real time. Additonal popup charts can reveal current deviation from setpoint for all zones.

Figure 4. Process screen

Recipe Load and Editor Screens

Recipes are created, modified, stored and retreived from the Recipe Editor screens. Recipe Editor 2 contains most of the necessary paramaters. Recipe Editor 2 screen contains field for more advanced functions like PID parameters and alarm levels.

Figure 5. Recipe Editor 1 and Recipe Editor 2 screens

Figure 1. Furnace Main Power Console

Figure 1. Furnace Main Power Console